Welcome! This instruction book details operation of the production machine, as of today, December 21st, 2025. It’s designed for operators with minimal prior experience.

Machine Overview & Purpose

This machine efficiently manufactures [product name will be inserted here]. It’s a crucial component of our production line, ensuring consistent quality and output.

Major Components Identification

Key parts include the main chassis, control panel, input/output conveyors, and the processing unit. Detailed visuals are found in Section 4.

Document Organization & Related Manuals

This manual covers all operational aspects. Refer to the maintenance schedule (Document #MS-2025) for upkeep and troubleshooting guides (Document #TG-01).

Operator Responsibilities & Authority

Operators are responsible for basic operation, quality checks, and reporting issues. Complex repairs require maintenance personnel; do not attempt self-repair;

Core Functionality: This automated production machine is engineered for the high-volume manufacturing of precision-engineered widgets, specifically model XR-7. Its primary purpose is to consistently produce components meeting stringent quality standards, minimizing waste and maximizing efficiency. The machine integrates several key processes – material feeding, forming, quality inspection, and automated packaging – into a single, streamlined operation.

Operational Context: It’s designed to operate within a controlled factory environment, requiring a stable power supply and adherence to outlined safety protocols. The machine’s output directly feeds into the subsequent assembly stage, making its reliable performance critical to overall production flow. Operators will primarily interact with the Human-Machine Interface (HMI) to monitor performance and address minor issues, as detailed in Section 6.

Intended Use: This machine is not intended for research and development or the production of non-approved components. Any deviation from specified parameters must be authorized by engineering personnel.

Key Assemblies: The machine comprises several critical assemblies. The Main Frame provides structural support. The Control Cabinet houses the PLC and power distribution systems. The Material Hopper feeds raw materials into the processing unit. The Forming Head performs the core shaping operation. The Inspection Station utilizes sensors to verify component quality.

Essential Subsystems: The Conveyor System transports parts between stations. The HMI Panel serves as the operator interface. The Emergency Stop System provides immediate shutdown capability. The Lubrication System ensures smooth operation and longevity. Detailed diagrams illustrating each component’s location are provided in Section 4, alongside corresponding part numbers.

Important Note: Familiarize yourself with the location and function of each component before operating the machine.

Manual Structure: This manual follows a logical progression, starting with machine overview and culminating in shutdown procedures. Each section builds upon previous information, ensuring a comprehensive understanding of operation. Cross-references are utilized extensively to link related topics.

Supporting Documentation: The Maintenance Schedule (MS-2025) details preventative maintenance tasks and intervals. The Troubleshooting Guide (TG-01) assists in diagnosing and resolving common issues. The Electrical Schematics (ES-2025) provide detailed wiring diagrams. The Parts Catalog (PC-2025) lists all replaceable components with part numbers.

Accessing Resources: All related manuals are available digitally on the shared network drive under the “Production Equipment” folder.

Core Duties: Operators are primarily responsible for safely operating the machine according to these instructions, performing routine quality checks on produced parts, and accurately documenting production counts. Maintaining a clean and organized work area is also essential.

Limitations: Operators do not have the authority to perform maintenance beyond basic cleaning or to attempt repairs on electrical or mechanical components. Any malfunctions or unusual noises must be immediately reported to a qualified maintenance technician.

Quality Control: Operators are the first line of defense for product quality. Any deviations from specifications should be flagged and documented. Refer to Section 5 for detailed quality inspection procedures.

Safety Precautions & Emergency Procedures

Critical Safety Information: Prioritize personal safety! This section details potential hazards, required safety equipment, and emergency shutdown protocols for this machine.

Potential Hazards & Risks

Warning! Operating this machine presents several potential hazards requiring constant vigilance. Mechanical dangers include pinch points on moving parts, especially during startup and shutdown sequences. Electrical hazards exist due to high-voltage components; never tamper with electrical panels.

Furthermore, operators must be aware of potential ergonomic risks associated with repetitive motions and prolonged standing. Noise levels may exceed safe limits, necessitating hearing protection. Material handling poses risks of strains and sprains.

Finally, ejected parts or material failures can create projectile hazards. Always wear appropriate personal protective equipment (PPE) as detailed in Section 3, and immediately report any unsafe conditions to your supervisor. Ignoring these risks could result in serious injury.

Safety Controls & Guards

Critical Safety Features: This machine incorporates multiple safety controls and guards to minimize operator risk. Light curtains surround access points, immediately halting operation upon beam interruption. Emergency stop buttons are strategically located for rapid shutdown in critical situations – familiarize yourself with their locations.

Physical guards enclose moving parts, preventing accidental contact; Interlock switches disable the machine if guards are removed or improperly positioned. A clearly labeled lockout/tagout procedure (refer to supplemental document LOTO-2025) must be followed during maintenance.

Regularly inspect all safety devices to ensure proper functionality. Report any damaged or malfunctioning controls immediately to maintenance personnel. Never bypass or disable safety features.

Personal Protective Equipment (PPE) Requirements

Mandatory PPE: To ensure operator safety, specific Personal Protective Equipment (PPE) is required when working with this machine. Safety glasses with side shields are mandatory at all times to protect against flying debris. Hearing protection, in the form of earplugs or earmuffs, is required due to the machine’s operational noise levels.

Closed-toe footwear is essential to prevent foot injuries. Gloves, specifically [specify glove type – e.g., nitrile], must be worn when handling materials or performing cleaning tasks. Avoid loose clothing or jewelry that could become entangled in moving parts.

Ensure all PPE is in good condition and properly fitted. Report any damaged or ill-fitting equipment immediately. Failure to comply with PPE requirements may result in disciplinary action.

Emergency Stop Procedures

Critical Safety Information: In any emergency situation, immediately activate the nearest Emergency Stop (E-Stop) button. These are prominently located on the main control panel and at each operator station – identified by a red mushroom-shaped head. Pressing an E-Stop instantly cuts power to all machine functions.

After activating an E-Stop, do not attempt to restart the machine. Notify a supervisor or maintenance personnel immediately to investigate the cause of the emergency. A documented investigation must occur before resuming operation.

Familiarize yourself with the location of all E-Stop buttons before operating the machine. Regular drills will be conducted to ensure proficiency in emergency procedures.

Powering On & Off the Machine

Essential Procedures: This section details safe startup and shutdown sequences, crucial for maintaining machine integrity and operator safety. Follow steps carefully!

Startup Sequence – Step-by-Step

Verify all safety guards are in place. Turn the main power switch to the ‘ON’ position. Observe the HMI for system initialization messages.

Normal Shutdown Procedure

Complete the current production cycle. Press the ‘Shutdown’ button on the HMI. Wait for complete system halt before switching off the main power.

Emergency Power-Down Procedure

Activate the nearest E-Stop button. This immediately cuts all power. Notify maintenance for investigation before restarting the machine.

Long-Term Storage Power-Off Instructions

Follow the normal shutdown procedure. Disconnect the main power cable. Cover the machine to protect from dust and environmental factors.

Prior to initiating the startup sequence, ensure the work area surrounding the machine is clear of obstructions and personnel. Visually inspect all safety guards and interlocks; confirm they are securely in place and functioning correctly. Do not bypass or disable any safety features. Next, verify the emergency stop buttons are readily accessible and operational.

Turn the main power switch, located on the machine’s rear panel, to the ‘ON’ position. Allow a brief moment for the internal systems to initialize. Observe the Human-Machine Interface (HMI) screen for the appearance of the startup sequence messages. The HMI will display a series of diagnostic checks.

Await confirmation that all systems have passed the self-test. If any error messages appear, consult the troubleshooting section of this manual or notify a qualified maintenance technician. Once the HMI indicates a ‘Ready’ status, the machine is prepared for job setup and operation.

To execute a normal shutdown, first ensure all production has ceased and no materials remain within the processing area of the machine. On the HMI, navigate to the ‘Shutdown’ screen and select ‘Normal Shutdown’. The machine will initiate a controlled stop sequence, halting all moving parts.

Allow the machine to complete the shutdown sequence without interruption. Do not attempt to manually override or stop any processes during this phase. Once the HMI displays a ‘Shutdown Complete’ message, the main power switch can be safely turned to the ‘OFF’ position.

Verify all indicator lights are extinguished before leaving the machine unattended. This confirms a complete power-down. Regular adherence to this procedure ensures longevity and prevents potential damage.

In the event of an immediate hazard or malfunction, initiate the Emergency Power-Down Procedure without delay. Immediately press the nearest Emergency Stop button – clearly marked in red – located on the control panel and various points around the machine. This will instantly cut power to all moving components.

Once the Emergency Stop is activated, locate the main power switch and turn it to the ‘OFF’ position. Do not attempt to restart the machine until a qualified maintenance technician has investigated and resolved the issue.

Report the incident to your supervisor immediately, detailing the circumstances leading to the emergency shutdown. A full investigation will be conducted before resuming operation.

If the machine will be inactive for more than one week, follow these Long-Term Storage Power-Off Instructions. First, complete a Normal Shutdown Procedure (see Section 3.2). Then, disconnect the main power cable from the wall outlet.

Cover the machine with a protective dust cover to prevent contamination. Ensure all lubricants remain at appropriate levels, as specified in the maintenance schedule. Periodically (every three months) visually inspect the machine for any signs of corrosion or damage.

Before restarting after long-term storage, have a qualified technician verify all systems are operational.

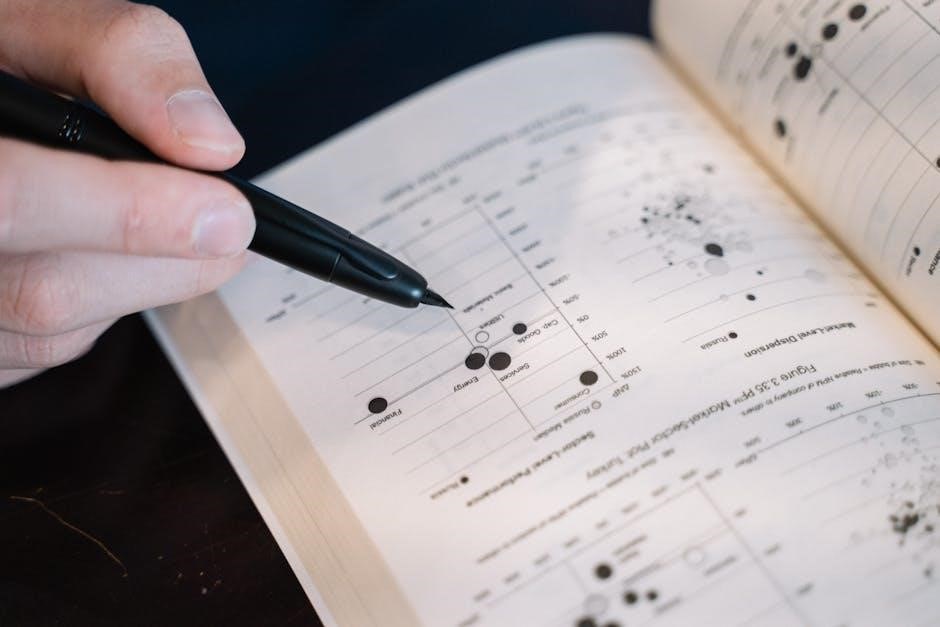

Visual Parts List & Identification

This section provides detailed images and part numbers for easy component identification. Verify received parts match this list before assembly or operation.

Component Breakdown with Images

This section presents a detailed visual guide to the machine’s key components. Each image is clearly labeled with corresponding part numbers for straightforward identification. We’ve included high-resolution photographs of each assembly, showcasing its location within the overall machine structure. Operators should familiarize themselves with these images to quickly locate and understand the function of each part.

Pay close attention to the orientation of components in the images. This is crucial for correct assembly and troubleshooting. Diagrams illustrate how parts connect, aiding in understanding the machine’s internal workings. Remember to cross-reference these visuals with the ‘Part Number Cross-Reference’ section to confirm component accuracy upon delivery and during maintenance. Consistent visual verification minimizes errors and ensures safe, efficient operation.

Part Number Cross-Reference

This table provides a comprehensive list correlating each component’s description with its unique part number. Accurate part number identification is vital for ordering replacements, performing maintenance, and ensuring compatibility. Operators should always verify received components against this list before installation. Discrepancies must be reported immediately to the maintenance department.

The table is organized alphabetically by component description for easy navigation. Each entry includes the part number, a brief description, and the quantity typically required for a standard machine build. This cross-reference ensures correct parts are used, preventing malfunctions and maintaining machine integrity. Refer to this section frequently during setup, repair, and routine inspections.

Assembly Diagram

The following pages contain a detailed, exploded-view assembly diagram of the production machine. This visual guide illustrates how all components fit together, aiding in understanding the machine’s structure and facilitating repairs. Each component is labeled with a corresponding reference number, directly linking to the Part Number Cross-Reference table (Section 4).

Operators should familiarize themselves with this diagram to quickly identify component locations. Use caution when interpreting the diagram; it represents a fully disassembled state. Always follow proper safety procedures when working on the machine. This diagram is a crucial resource for troubleshooting and component replacement, ensuring efficient maintenance and minimizing downtime.

Received Component Verification

Upon receiving any components for the production machine, immediate verification is crucial. Compare the physical parts against the Component Breakdown (Section 4) and the Part Number Cross-Reference list. Ensure all received items match the purchase order and packing slip. Document any discrepancies – missing parts, damage, or incorrect part numbers – immediately on the Receiving Inspection Report (Form RIR-2025).

Do not install any component that fails verification. Contact the purchasing department and your supervisor to resolve the issue before proceeding. Proper verification prevents installation errors and ensures the machine operates safely and efficiently. This step is vital for maintaining product quality and avoiding costly delays.

Job Setup & Configuration

This section details preparing the machine for each production run. It covers tooling changes, settings adjustments, and initial quality checks for optimal output.

Tooling & Component Changeover

Refer to the specific job traveler for required tooling. Carefully remove old components and install new ones, verifying proper alignment and secure fastening.

Production Run Settings Adjustment

Input the correct parameters into the HMI based on the job traveler. Double-check all settings before initiating the production run to avoid errors.

Troubleshooting During Setup

If issues arise during setup, consult the troubleshooting guide (TG-01) or contact maintenance. Do not force any components or settings.

Packaging Setup Instructions

Configure the packaging line according to the job traveler. Ensure proper labeling and containerization for finished products, maintaining quality standards.

Prior to commencing any production run, a meticulous tooling and component changeover is essential. Always consult the corresponding job traveler document – this is your primary guide. Before removing existing tooling, ensure the machine is powered down and locked out according to safety procedures (Section 2). Carefully document the removal process, noting the orientation and condition of each component.

New tooling should be inspected for damage before installation. Verify that all components match the specifications outlined in the job traveler and Section 4 (Visual Parts List). During installation, ensure proper alignment and secure fastening, utilizing the correct torque settings as indicated. Double-check all connections and guards are in place before proceeding. Any discrepancies or missing parts must be reported to a supervisor immediately. A properly executed changeover minimizes downtime and ensures product quality.

Following tooling changeover, precise adjustment of production run settings is critical for optimal performance. Access the Human-Machine Interface (HMI) – detailed navigation is found in Section 6. Input the parameters specified in the job traveler, including speed, temperature, pressure, and cycle time. Verify each setting before confirming.

Initiate a test run with minimal material to validate settings. Closely monitor key performance indicators (KPIs) displayed on the HMI, such as output rate and reject count. Fine-tune adjustments as needed, referencing the troubleshooting guide (Document #TG-01) for common issues. Document all adjustments made. Confirm settings with a supervisor before commencing full production. Accurate settings guarantee consistent product quality and minimize waste.

Setup can occasionally present challenges. If the machine fails to recognize newly installed tooling, double-check the sensor connections and ensure proper alignment. Error messages on the HMI (Section 6) provide valuable clues; consult Document #TG-01 for specific code definitions.

If material jams during initial setup runs, verify feed rates and component positioning. Ensure all safety guards are in place before attempting to clear any obstructions. For persistent issues, immediately notify a maintenance technician. Do not force components or override safety systems. Document all troubleshooting steps taken, including error codes and attempted solutions, for future reference and efficient problem resolution.

Proper packaging is vital for product integrity. Before each production run, confirm the correct box size and cushioning materials are available. Refer to the job traveler for specific packaging requirements. Ensure the automated packaging line is clear of obstructions and properly calibrated.

Verify label printers are functioning and loaded with the correct labels. Inspect conveyor belts for damage or debris. During initial runs, closely monitor package weight and dimensions to confirm accuracy. Any discrepancies should be reported immediately to the quality control department. Document packaging changes or adjustments made during setup for consistent results.

Machine Operation & Monitoring

Consistent operation is key! This section details standard procedures, HMI navigation, KPI monitoring, and quality control checks during production runs.

Standard Operating Procedures

Follow established steps for each cycle. Maintain awareness of machine status and promptly address any deviations from normal operation.

Human-Machine Interface (HMI) Navigation

The HMI displays critical data. Use touchscreen controls to adjust settings and monitor performance. Refer to the HMI guide for details.

Monitoring Key Performance Indicators (KPIs)

Track output rate, cycle time, and error rates. Report any significant fluctuations to supervision for investigation.

Quality Control Checks During Production

Regularly inspect parts for defects. Document findings and adjust machine settings as needed to maintain quality standards.

Adherence to these procedures ensures safe and efficient production. Begin each cycle by verifying material presence on the input conveyor, confirming the correct tooling is installed, and initiating the start sequence via the HMI. Continuously monitor the machine’s operation, paying close attention to the displayed parameters like pressure, temperature, and cycle time. Do not attempt to adjust settings without proper authorization or understanding of their impact.

Regularly inspect produced parts for visual defects, referencing the quality control standards outlined in Section 5. Any discrepancies must be immediately reported to a supervisor. Maintain a clean and organized workspace, removing scrap material and ensuring unobstructed access to controls. Never bypass safety interlocks or operate the machine with guards removed. These procedures are designed for operators with limited experience, prioritizing safety and consistent output. Remember, consistent adherence is paramount for optimal performance.

The HMI is your primary control point for the machine. The main screen displays critical operational data: cycle count, runtime, and error messages. Use the touchscreen to navigate between screens via the clearly labeled icons. The ‘Settings’ icon allows authorized personnel to adjust production parameters – do not modify these without training. The ‘Diagnostics’ screen provides detailed machine status and troubleshooting information.

To acknowledge alarms, press the illuminated ‘Reset’ button. The ‘Manual Mode’ option, accessible with a supervisor override, allows for individual component testing. Familiarize yourself with the layout; a simplified diagram is located on the control panel. Remember, the HMI is designed for ease of use, even for operators with minimal technical experience. Refer to the troubleshooting guide if issues arise.

Regular KPI monitoring is vital for maintaining production efficiency; Key indicators displayed on the HMI include units produced per hour, cycle time, and reject rate. Track these values throughout your shift and note any significant deviations from established targets. A sudden increase in rejects signals a potential quality issue requiring immediate attention. Cycle time fluctuations may indicate mechanical problems or improper setup.

Record KPI data in the provided log sheet at the end of each shift. This data helps identify trends and optimize machine performance. Report any consistent anomalies to your supervisor. Proactive monitoring prevents costly downtime and ensures consistent product quality. Remember, consistent attention to KPIs is crucial for successful operation.

Consistent quality control is paramount. Every hour, visually inspect at least ten randomly selected units for defects – scratches, blemishes, or dimensional inaccuracies. Use the provided calipers and gauges to verify critical measurements against the specification sheet (Document #QS-2025). Document all inspection results on the quality control checklist.

If defects are detected, immediately notify your supervisor and halt production. Do not attempt to adjust the machine without authorization. Clearly label any rejected parts and place them in the designated quarantine area. Maintaining rigorous quality checks ensures we deliver superior products and minimize waste. Your diligence is essential for upholding our standards.

Shutdown & Job Completion

Job closure is critical! Follow these steps for safe shutdown, accurate reporting, and thorough cleaning, ensuring readiness for the next production run.

End-of-Shift Shutdown Procedure

Power down the machine using the normal shutdown procedure (Section 3). Secure all materials and tools. Report any issues immediately.

Job Completion Reporting

Record production quantities and any downtime on the job completion report (Form #JR-2025). Submit to your supervisor for review.

Cleaning & Maintenance Tasks

Wipe down all surfaces and remove debris. Refer to the maintenance schedule for any required preventative maintenance tasks.

Prior to leaving for the day, a complete and orderly shutdown is essential for both safety and maintaining machine integrity. Begin by ensuring all produced parts have been removed from the output conveyor and properly packaged according to packaging instructions (Section 5). Next, navigate to the HMI (Human-Machine Interface) and initiate the ‘Normal Shutdown’ sequence as detailed in Section 3.

Confirm the machine has fully stopped and all moving parts have ceased operation. Visually inspect the work area for any dropped tools, debris, or potential hazards. Ensure all safety guards are in place and functioning correctly. Finally, complete the end-of-shift log, noting any unusual occurrences or maintenance needs. Report any concerns to the supervisor before departing. A consistent shutdown procedure prevents unexpected issues and ensures a smooth start for the next shift.

Upon finishing a production run, accurate reporting is critical for tracking efficiency and identifying areas for improvement. Immediately after the final shutdown (Section 7), complete the ‘Job Completion Report’ form – either digitally via the HMI or the paper form located near the control panel. This report requires detailed information including the total quantity of good parts produced, the number of rejected parts, and any noted quality issues.

Document any tooling changes made during the run (Section 5) and the total operating time. Include a brief summary of any significant challenges encountered and how they were resolved. Submit the completed report to your supervisor for review and data entry. Thorough reporting ensures accurate production records and supports continuous improvement efforts.

Regular cleaning and basic maintenance are essential for optimal machine performance and longevity. Following each shift, or at job completion, remove any accumulated debris from the machine surfaces using a brush and vacuum. Do not use compressed air, as it can spread contaminants. Wipe down the control panel with a damp, lint-free cloth.

Inspect and empty the scrap collection bins. Refer to the detailed maintenance schedule (Document #MS-2025) for lubrication points and filter replacement intervals. Report any unusual noises, leaks, or malfunctions to maintenance personnel immediately. Consistent upkeep minimizes downtime and ensures continued production quality.