Overhead Door RSX Manual: A Comprehensive Guide

This comprehensive guide details the installation‚ troubleshooting‚ and maintenance of the RSX Commercial/Industrial Door Operator‚ referencing A.O. Smith’s expertise.

Access manuals‚ spec sheets‚ and wiring diagrams for Overhead Door products‚ with technical advice available at 800-275-6187.

The Overhead Door RSX operator represents a robust solution for commercial and industrial door applications‚ benefiting from A.O. Smith’s technological contributions. This operator is designed for reliability and longevity‚ incorporating advanced features for smooth and safe operation.

Installation manuals provide crucial information for proper setup and maintenance‚ ensuring optimal performance. Understanding the operator’s components and functions‚ as detailed in available literature‚ is key to maximizing its lifespan and minimizing potential issues. This guide will help you navigate the complexities of the RSX system.

Safety Precautions and Warnings

Prior to installation or maintenance of the Overhead Door RSX operator‚ carefully review all safety information within the installation manual. The terms “Danger‚” “Warning‚” and “Caution” highlight critical safety concerns.

Disconnect power before performing any work. Ensure the door is properly secured to prevent accidental closure during servicing. Improper installation or maintenance can lead to serious injury or damage. Always follow established safety protocols and consult qualified personnel when needed.

RSX Operator Components and Identification

The RSX Commercial/Industrial Door Operator comprises several key components. These include the operator itself‚ the trolley and rail system facilitating door movement‚ and the operator control box managing functionality.

Understanding each component’s role is crucial for proper installation and troubleshooting. Familiarize yourself with the trolley’s interaction with the rail‚ and the control box’s indicators and buttons‚ as detailed in the installation manual.

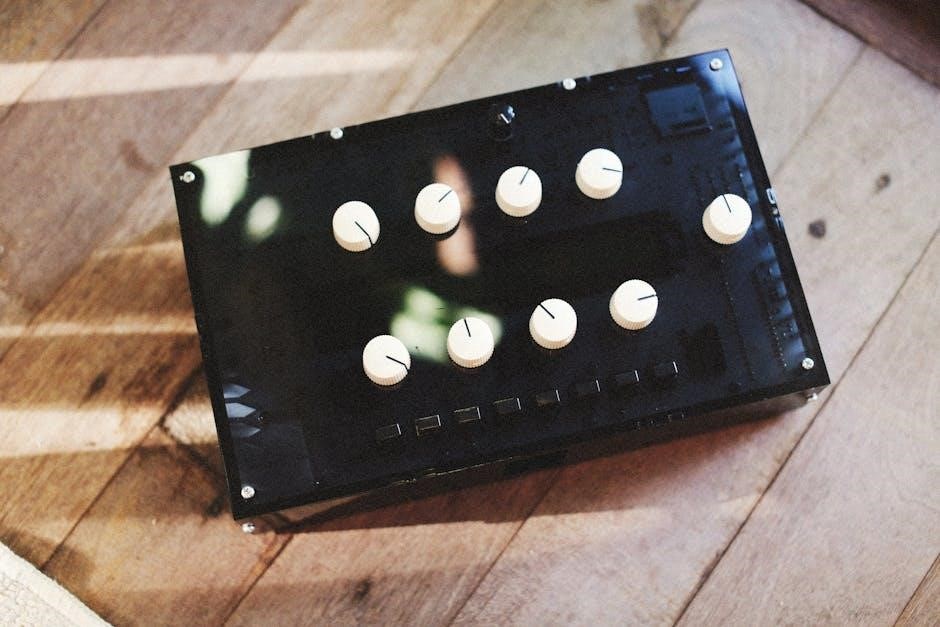

Operator Control Box Overview

The RSX operator control box serves as the central hub for system operation and programming. It houses LED indicator lights displaying operational status and potential fault conditions. Various buttons enable programming modes and manual control of the door.

Refer to the installation manual for a detailed explanation of each button’s function and the meaning of the LED indicators‚ ensuring safe and effective operation of the Overhead Door system.

Trolley and Rail System Details

The RSX operator utilizes a robust trolley and rail system designed for smooth and reliable door operation. Proper alignment and secure mounting of these components are crucial for optimal performance and longevity.

The installation manual provides detailed instructions regarding trolley travel‚ rail support spacing‚ and necessary hardware. Ensure all connections are tightened to the specified torque values‚ referencing the manual for specific guidelines.

Installation Procedures for the RSX Operator

Installation of the RSX Commercial/Industrial Door Operator requires adherence to the detailed procedures outlined in the provided manual. This includes careful mounting of the operator to the header‚ ensuring proper alignment and secure fastening.

Subsequently‚ connecting the trolley and door arm demands precision‚ referencing the manual’s diagrams for correct linkage. Prioritize safety throughout the process‚ and always verify all connections before operation.

Mounting the Operator to the Header

Mounting the RSX operator to the header is a critical step‚ demanding a structurally sound header capable of supporting the operator’s weight and operational forces. The installation manual provides specific guidance on header reinforcement if necessary.

Ensure precise alignment and utilize appropriate mounting hardware‚ securely fastening the operator to the header. Double-check all bolts and connections for tightness‚ referencing the manual’s torque specifications for optimal stability.

Connecting the Trolley and Door Arm

Connecting the trolley and door arm requires careful attention to ensure smooth and reliable door operation. The RSX operator’s installation manual details the correct arm length and trolley positioning for your specific door size and weight.

Securely attach the door arm to both the trolley and the door‚ verifying proper alignment and range of motion. Confirm all connections are tight and utilize the specified hardware to prevent disengagement during operation‚ as outlined in the manual.

Wiring and Electrical Connections

Wiring the RSX operator demands strict adherence to local electrical codes and the manual’s guidelines. Ensure the power supply meets the operator’s requirements before commencing any connections. Incorrect wiring can lead to malfunction or safety hazards.

Proper grounding is crucial for safe operation. Carefully connect all wires according to the wiring diagram‚ paying close attention to safety devices. Double-check all connections before restoring power‚ referencing the manual for detailed instructions.

Power Supply Requirements

The RSX operator necessitates a dedicated electrical circuit‚ conforming to local and national electrical codes. Verify the voltage and amperage supplied align precisely with the operator’s specifications detailed in the installation manual.

Insufficient power can cause operational issues or damage the operator. A properly sized circuit breaker is essential for protection. Always disconnect power before performing any electrical work‚ and consult a qualified electrician if unsure.

Connecting Safety Devices

Properly connecting safety devices is paramount for preventing accidents. This includes photo eyes‚ edge sensors‚ and warning lights‚ all crucial for RSX operator functionality.

Refer to the installation manual for precise wiring diagrams and ensure all connections are secure. Regularly test these devices to confirm they are functioning correctly‚ halting and reversing door travel upon obstruction. Failure to do so compromises safety and voids warranty stipulations.

Programming and Adjustments

Precise programming and adjustments are vital for optimal RSX operator performance and safety. This involves configuring limit switches to define door travel boundaries‚ ensuring smooth operation.

Force adjustment settings require careful calibration to prevent damage or injury. Consult the manual for detailed instructions on accessing programming modes via the control box‚ utilizing LED indicators to confirm settings. Incorrect adjustments can compromise safety features and void the A.O. Smith warranty.

Limit Switch Adjustment

Limit switch adjustment precisely defines the RSX operator’s up and down travel limits. Incorrect settings can cause the door to not fully open or close‚ or even result in damage.

Refer to the installation manual for specific procedures‚ typically involving incremental adjustments while observing door movement. Ensure both up and down limits are accurately set before proceeding. Proper adjustment is crucial for safe and reliable operation‚ aligning with A.O. Smith’s quality standards.

Force Adjustment Settings

Force adjustment settings on the RSX operator control the amount of power applied during door travel. These settings are vital for overcoming obstacles and ensuring smooth operation‚ but must be carefully calibrated.

The installation manual details procedures for adjusting both opening and closing force. Improper settings can compromise safety; excessive force risks damage‚ while insufficient force may prevent closure. Refer to the manual and prioritize safety when making adjustments‚ reflecting A.O. Smith’s commitment to reliable performance.

Troubleshooting Common Issues

Troubleshooting the RSX operator often begins with verifying basic connections and power supply. If the operator isn’t responding‚ check the control box and wiring. Door travel problems may indicate limit switch misadjustments or obstructions.

The installation manual provides detailed guidance for diagnosing and resolving these issues. Remember to prioritize safety and consult the manual before attempting repairs. Overhead Door Factory Technical Advice is available at 800-275-6187 for further assistance‚ leveraging A.O. Smith’s expertise.

Operator Not Responding

If the RSX operator fails to respond‚ initially verify the power supply to the control box. Inspect all wiring connections for looseness or damage‚ referencing the installation manual’s wiring diagrams. Check the LED indicator lights on the control box for error codes‚ as detailed in the manual.

Confirm safety devices aren’t interrupting the circuit. For persistent issues‚ contact Overhead Door Factory Technical Advice at 800-275-6187‚ utilizing A.O. Smith’s support resources.

Door Travel Problems

If experiencing issues with door travel – stopping mid-cycle or inconsistent movement – begin by checking the limit switch adjustments‚ as outlined in the RSX operator manual. Verify the trolley and rail system are free of obstructions and properly lubricated. Inspect the door itself for binding or damage.

Adjust force settings cautiously‚ following manual instructions. For complex issues‚ consult Overhead Door’s technical support at 800-275-6187‚ leveraging A.O. Smith’s expertise.

Maintenance and Lubrication

Regular inspection of the RSX operator is crucial for longevity. A checklist should include verifying all fasteners are tight‚ checking wiring connections‚ and inspecting the trolley and rail system for wear. Proper lubrication‚ using recommended lubricants detailed in the manual‚ minimizes friction and ensures smooth operation.

A.O. Smith’s technology benefits from consistent maintenance. Refer to the manual for specific lubrication points and frequencies‚ maximizing the operator’s lifespan and performance.

Regular Inspection Checklist

A thorough inspection should verify all mounting bolts are secure‚ ensuring the operator remains firmly attached to the header. Examine the trolley and rail system for any signs of wear‚ damage‚ or obstructions. Inspect all wiring connections for tightness and insulation integrity.

Confirm proper operation of safety devices‚ and review the manual for A.O. Smith’s recommended maintenance schedule. Document all findings and address any issues promptly to maintain optimal performance.

Recommended Lubricants

Utilize a high-quality lithium-based grease for lubricating the trolley wheels‚ rail system‚ and other moving components of the RSX operator. Avoid using WD-40 or silicone-based lubricants‚ as they can attract dust and debris.

A;O. Smith suggests a lubricant with a viscosity appropriate for the operating temperature range. Regularly apply lubricant to ensure smooth operation and prevent premature wear‚ referencing the manual for specific guidance.

Understanding the RSX Operator Control Box

The RSX operator’s control box houses critical components for operation and programming. LED indicator lights display system status‚ signaling normal function or potential issues. Various buttons facilitate programming modes and adjustments‚ allowing customization of door travel and safety features.

Refer to the manual for detailed explanations of each button’s function and LED light meaning‚ ensuring proper configuration and troubleshooting. A.O. Smith’s design prioritizes user accessibility.

LED Indicator Lights and Their Meanings

The RSX operator control box utilizes LED indicator lights to communicate system status. A solid green LED typically signifies normal operation‚ while a flashing green light may indicate a cycle in progress. Red LEDs generally signal faults or errors requiring attention‚ as detailed in the manual.

Consult the manual for a comprehensive list of LED patterns and their corresponding meanings‚ enabling quick diagnosis of potential issues. A.O. Smith’s clear indicators aid in efficient troubleshooting.

Button Functions and Programming Modes

The RSX operator control box features buttons for various functions‚ including up‚ down‚ stop‚ and programming access. Entering programming mode allows adjustments to limit switches and force settings‚ as outlined in the installation manual.

Specific button combinations initiate different programming sequences. Refer to the manual for detailed instructions on utilizing these modes‚ ensuring proper configuration and operation of your Overhead Door system‚ leveraging A.O. Smith technology.

Remote Control Operation and Programming

The RSX operator supports remote control functionality for convenient operation. Programming a new remote involves a specific pairing procedure detailed in the manual‚ ensuring secure access to your Overhead Door system.

Troubleshooting remote issues‚ such as lack of response‚ often involves checking battery levels and re-pairing the device. Refer to the manual for step-by-step guidance‚ benefiting from A.O. Smith’s reliable technology and support resources.

Pairing a New Remote

To pair a new remote with your RSX operator‚ consult the manual for precise instructions. Typically‚ this involves entering a programming mode on the operator’s control box‚ often initiated by a specific button sequence.

The remote then transmits a signal‚ establishing a connection. Successful pairing is usually indicated by an LED confirmation on the control box. A.O. Smith’s design prioritizes secure and straightforward remote access for your Overhead Door.

Troubleshooting Remote Issues

If your remote isn’t functioning‚ first check the battery. A weak battery is a common cause of signal failure. Ensure there’s no obstruction between the remote and the RSX operator’s receiver. If problems persist‚ re-pairing the remote may be necessary‚ following the steps outlined in the manual.

A.O. Smith’s Overhead Door systems are designed for reliability‚ but occasional remote glitches can occur. Refer to the manual or contact support for further assistance.

A.O. Smith and Overhead Door Collaboration

A.O. Smith brings decades of expertise in motor technology and engineering to the Overhead Door operator systems‚ like the RSX. This collaboration ensures robust and reliable performance. A.O. Smith commenced exporting in 1970‚ establishing a strong distribution network.

Their commitment extends to providing comprehensive warranty information and dedicated support for RSX operators‚ guaranteeing customer satisfaction and long-term operational efficiency.

A.O. Smith’s Role in Door Operator Technology

A.O. Smith’s pivotal role centers on advanced motor design and manufacturing‚ crucial for the RSX operator’s functionality. As an innovator with patented glass coating processes‚ they maximize component lifespan and efficiency. Their expertise ensures dependable operation in demanding commercial and industrial environments.

A.O; Smith consistently delivers high-quality components‚ contributing to the RSX’s reputation for durability and performance‚ backed by extensive research and development.

Warranty Information and Support

Overhead Door and A.O. Smith collaborate to provide robust warranty coverage for the RSX operator‚ protecting against manufacturing defects. Specific terms and durations vary; consult your official RSX documentation for details.

For technical support‚ troubleshooting assistance‚ or warranty claims‚ contact Overhead Door Factory Technical Advice at 800-275-6187. Access comprehensive resources and support through authorized Overhead Door distributors and the A.O. Smith website.

RSX Fire Door Operator Specifics

RSX Fire Door Operators adhere to stringent fire door compliance standards‚ ensuring reliable operation during emergency situations. Proper installation and maintenance are crucial for life safety systems.

Familiarize yourself with the RSX Fire Door Operator Manual for detailed emergency release procedures. Regular testing and inspection are vital to confirm functionality. A.O. Smith’s technology contributes to the operator’s dependable performance in critical applications.

Fire Door Compliance Standards

RSX Fire Door Operators must meet rigorous standards for functionality and reliability during fire events. These standards dictate requirements for operation‚ monitoring‚ and emergency release mechanisms.

Compliance ensures the door will open reliably when signaled‚ facilitating safe egress. Adherence to these standards‚ detailed in the RSX manual‚ is paramount for building safety and code compliance‚ leveraging A.O. Smith’s commitment to safety technology.

Emergency Release Procedures

RSX Fire Door Operators feature a manual release mechanism for use during power outages or system failures. This allows for manual operation of the fire door‚ ensuring egress isn’t blocked.

The manual details step-by-step instructions for safe and effective release‚ emphasizing the importance of understanding the system before attempting operation. Proper training and adherence to these procedures‚ supported by A.O. Smith’s engineering‚ are crucial for safety.

Accessing Additional Resources and Support

Overhead Door Factory Technical Advice is readily available by calling 800-275-6187 for immediate assistance with your RSX operator. Explore A.O. Smith’s Product Literature Library online for brochures‚ catalogs‚ and detailed spec sheets.

Download manuals‚ including the RSX Fire Door Operator Manual‚ directly from their website. These resources‚ combined with expert support‚ ensure comprehensive assistance for installation‚ troubleshooting‚ and ongoing maintenance of your door system.